Delivering Electronic Grade Polishing Resin to Malaysia

Delivering Electronic Grade Polishing Resin to Malaysia for Sapphire Wafer Production

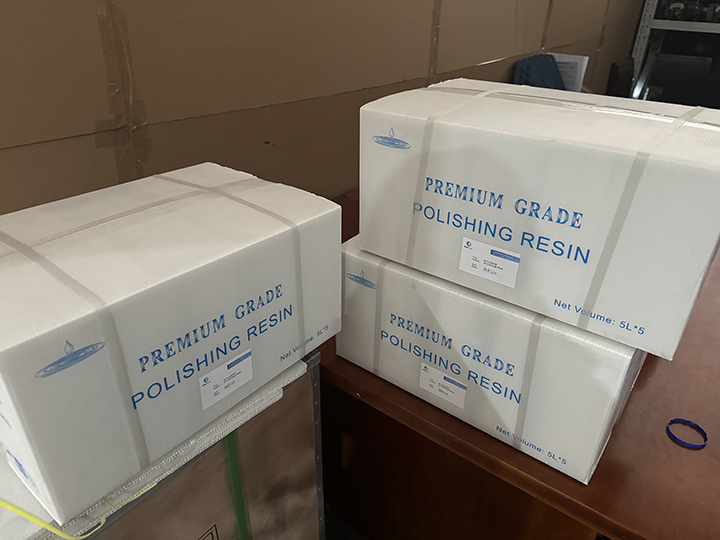

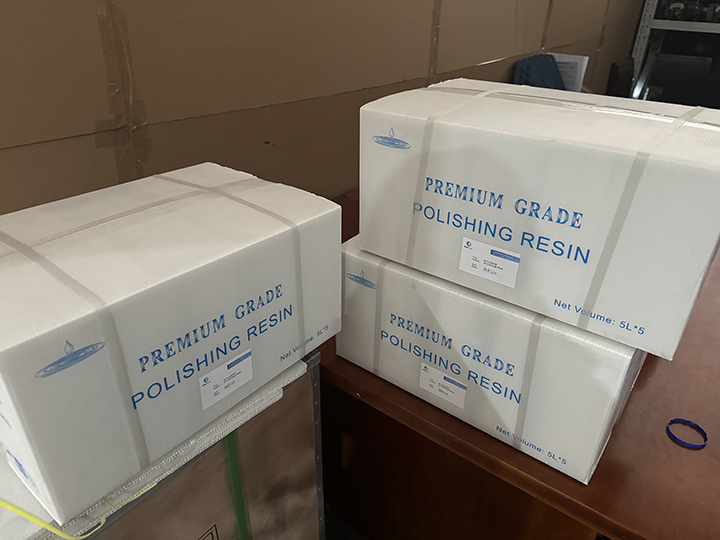

In the heart of technological advancement, precision and quality are paramount. We're excited to announce the successful delivery of our MR120 polishing resin to Malaysia, where it will play a crucial role in the production of sapphire wafers.

Our MR120 electronic grade polishing resin is meticulously engineered to meet the demanding requirements of semiconductor manufacturing, particularly in the production of sapphire wafers. Comprising a blend of high-quality cation and anion exchange resins, MR120 ensures exceptional water purity, crucial for the precision processing of sapphire crystals.

Sapphire wafers, renowned for their durability and optical properties, are essential components in various electronic devices, including LEDs, smartphones, and optical windows. To meet the stringent standards of sapphire wafer fabrication, our MR120 resin undergoes rigorous quality control and testing, ensuring consistent performance and reliability.

The choice of MR120 resin for our Malaysian customer's sapphire wafer production underscores our commitment to delivering cutting-edge solutions that optimize manufacturing processes and enhance product quality. Its exceptional ion exchange capacity and regeneration efficiency enable our customers to achieve the highest purity levels in their water treatment systems, resulting in flawless sapphire crystals for their applications.

In the heart of technological advancement, precision and quality are paramount. We're excited to announce the successful delivery of our MR120 polishing resin to Malaysia, where it will play a crucial role in the production of sapphire wafers.

Our MR120 electronic grade polishing resin is meticulously engineered to meet the demanding requirements of semiconductor manufacturing, particularly in the production of sapphire wafers. Comprising a blend of high-quality cation and anion exchange resins, MR120 ensures exceptional water purity, crucial for the precision processing of sapphire crystals.

Sapphire wafers, renowned for their durability and optical properties, are essential components in various electronic devices, including LEDs, smartphones, and optical windows. To meet the stringent standards of sapphire wafer fabrication, our MR120 resin undergoes rigorous quality control and testing, ensuring consistent performance and reliability.

The choice of MR120 resin for our Malaysian customer's sapphire wafer production underscores our commitment to delivering cutting-edge solutions that optimize manufacturing processes and enhance product quality. Its exceptional ion exchange capacity and regeneration efficiency enable our customers to achieve the highest purity levels in their water treatment systems, resulting in flawless sapphire crystals for their applications.

Last One :

Next Article :

Related Products

-

GD200 Thiourea Chelating Resin for Precious Metal Extraction ResinAppearance: Milky to light yellow opacity spherical beadsIonic form:H+Volume complete exchange capacity(mmol/ml):≥1.2

GD200 Thiourea Chelating Resin for Precious Metal Extraction ResinAppearance: Milky to light yellow opacity spherical beadsIonic form:H+Volume complete exchange capacity(mmol/ml):≥1.2 -

001X7 Cation Exchange ResinIonic form:Na+Appearance: Claybank to tan transparent spherical particle.The degree of crosslinking : 7%.

001X7 Cation Exchange ResinIonic form:Na+Appearance: Claybank to tan transparent spherical particle.The degree of crosslinking : 7%. -

D005 Catalyst ResinAppearance: Gray opaque spherical particles.Ionic form:H+Volume complete exchange capacity(mmol/ml):≥4.7

D005 Catalyst ResinAppearance: Gray opaque spherical particles.Ionic form:H+Volume complete exchange capacity(mmol/ml):≥4.7

Message